The aim of this project is to design an integrated Sub-Assembly of a component from a Dong Cheng Impact Wrench using the concepts of Design for Additive Manufacturing (DfAM). The idea is to amplify the product performance by means of synthesis of shapes, sizes, hierarchical structures, as well as material compositions, restricted to AM capabilities.

This will enable new opportunities for customization, improvements in performance, multi-functionality and lower overall manufacturing costs. By performing part consolidation, the capability of material complexity leads to wider explorations of design possibilities. As a result, it reduces the number of assembly operations, production cost and perplexity for products.

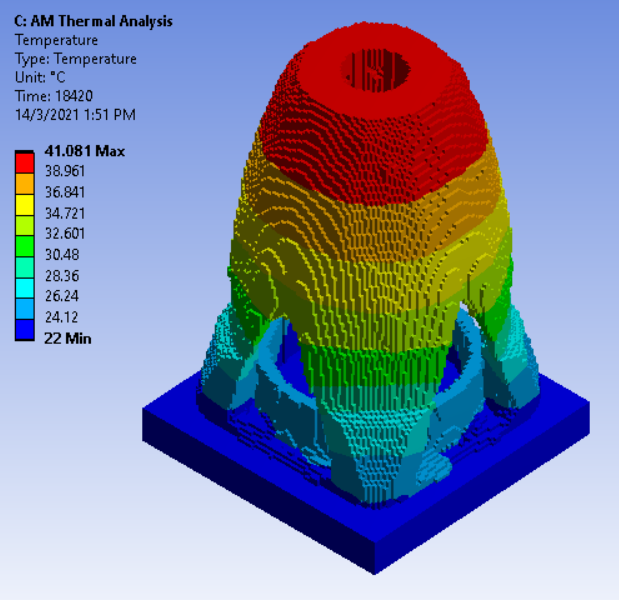

The process includes 3D scanning of the initial Sub-Assembly, Print Simulation to predict the stresses, distortion and thermal strain that the part will undergo during the printing process, Topology Optimization to reduce the weight of the Sub-Assembly, Process Simulation to simulate printing processes, distortion compensation and build failure prediction, and lastly, 3D printing the final product.

Sub-Assembly of a Dong Cheng Impact Wrench

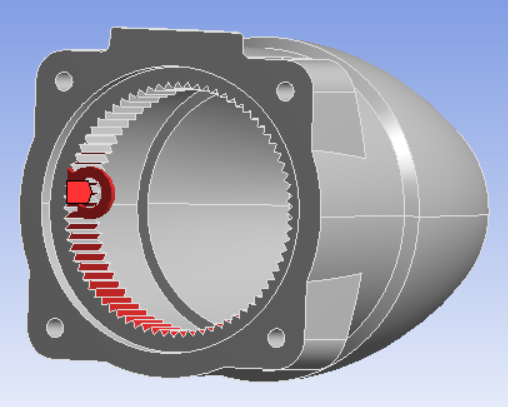

CAD Modelling of a Sub-Assembly

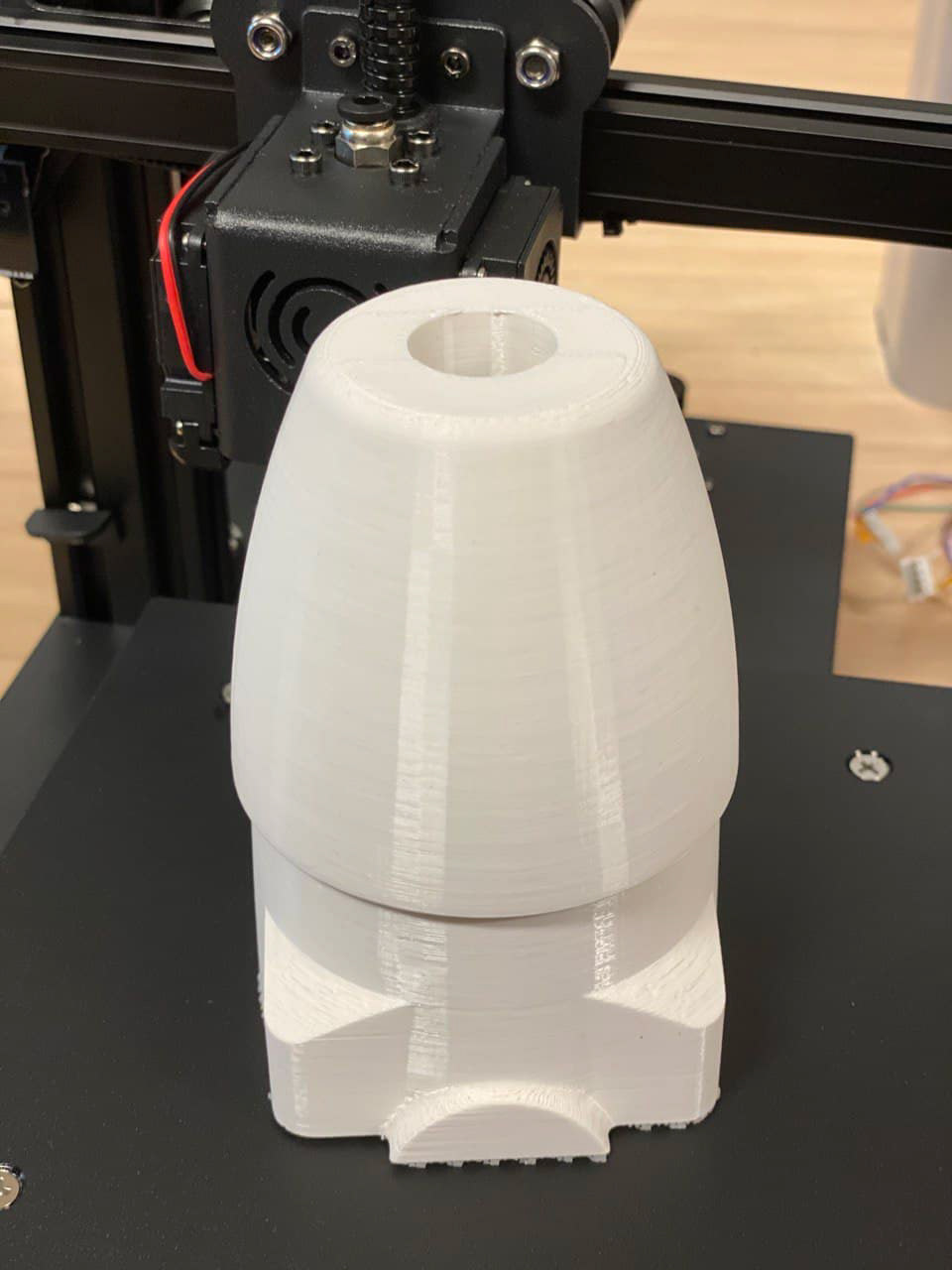

3D Printed of the Sub-Assembly

Topology Optimization

After weight reduction process of a sub-assembly

Structural Analysis of a Sub-Assembly

Thermal Analysis of a Sub-Assembly

3D Printed after the Topology Optimization